The partnership between the ITA and Brazil’s Ministry of Development, Industry, Commerce, and Services (MDIC) now supports 11 projects representing USD 17.5 billion of investment potential across the country, reinforcing Brazil’s climate leadership.

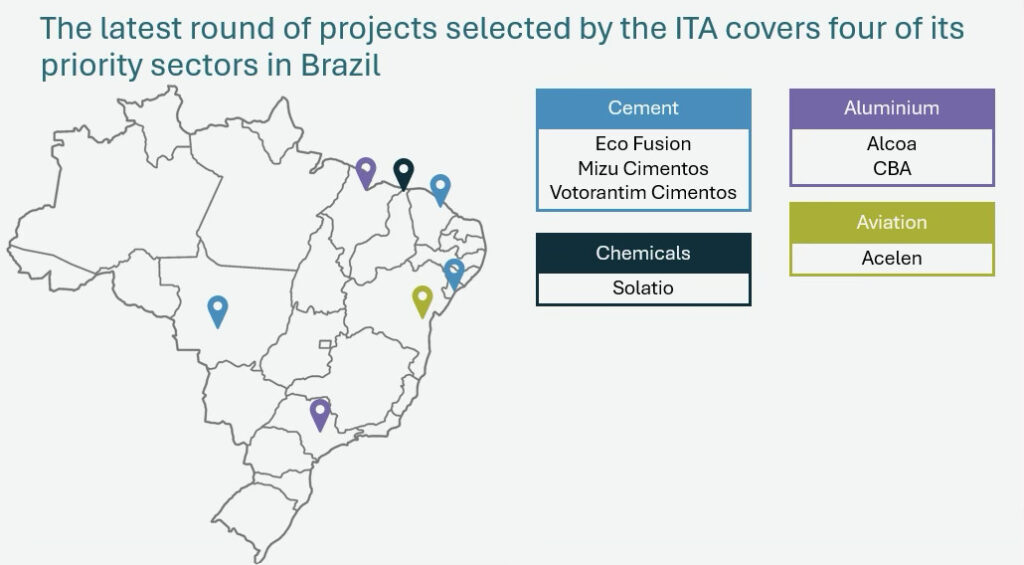

São Paulo, May 14th, 2025 – Today, the Industrial Transition Accelerator (ITA) has selected seven new clean industrial projects to support in partnership with the Brazilian Ministry of Development, Industry, Commerce, and Services (MDIC). This latest round of projects stands out for its high decarbonisation ambition and innovative solutions to tackle emissions in four of the ITA’s priority sectors in Brazil: chemicals, aviation, aluminium, and cement. Selected projects will receive dedicated bespoke support from the ITA to identify barriers and mobilise domestic and international industry, clean energy, demand, and finance solutions that advance those projects toward final investment decision.

Collectively representing a significant investment, exceeding USD 7.5 billion, the latest round of selected projects have high potential to accelerate clean industrial solutions in various parts of Brazil, further strengthening the country’s position as a leader in the energy transition in Latin America and globally.

As high-ambition projects that are leading the market, the ITA is proud to include projects under development by the following companies and consortia in its Project Support Programme in Brazil: 1) Solatio, 2) Acelen, 3) Votorantim Cimentos, 4) Mizu Cimentos, 5) the Eco Fusion consortium, 6) Alcoa, and 7) Companhia Brasileira de Alumínio (CBA). The last five of these seven projects are being announced publicly today for the first time.

“These Brazilian clean industry projects represent flagship efforts within their respective sectors and have the potential to show the way toward a more economically and environmentally sustainable industry across Brazil and beyond.” says Faustine Delasalle, Executive Director of the ITA. “We are committed to supporting these projects by mobilising the Brazilian value chain domestically and internationally, as well as policymakers, and financial institutions to make them bankable and fast track investment decisions.”

“The projects selected by the ITA showcase the ambition and progress of green neoindustrialisation taking place across Brazil,” says Rodrigo Rollemberg, Secretary of Green Economy, Decarbonisation, and Bioindustry of MDIC. “We look forward to further deepening our valued partnership with the ITA to promote and support these projects to become a reality.”

The seven newly-selected projects encompass a diversity of sectors, locations, technologies, project types and maturities, allowing a broad and deep understanding of the challenges faced by projects in Brazil, which will enable the ITA to offer innovative and tailored solutions. From the chemicals and aviation sectors, the projects represent large new facilities which could produce products with significantly lower emissions compared to conventional equivalents.

- The Solatio H2 Piauí project has developed 14 GW of renewables in a verticalized structure to supply a grid-connected industrial plant of green hydrogen and ammonia under development with a total capacity of 3 GW. The production capacity will reach 2.2 million tonnes per annum (Mtpa) of green ammonia by 2030.

- Acelen Renewables is developing an innovative project to produce advanced renewable fuels from macauba oil – a plant native to Brazil. The company will develop an integrated business, from seed to fuel, comprised of an R&D and Germination Center – Agripark with the capacity to produce 10.5 million seedlings per year, a 180 kilohectare macauba plantation, 5 milling plants to extract the oil and co-products from the macauba, and 1 biorefinery to process the macauba oil into fuel. The project aims to produce 1 billion litres of renewable fuels per year, including sustainable aviation fuel (SAF) and renewable diesel (HVO).

In the cement sector, the three selected projects are implementing measures considered crucial for bringing existing facilities to net zero. Cement decarbonization can only be achieved through a combination of measures, including clinker substitution, fuel switching, and carbon capture utilisation and storage. These projects aim to apply at least one of these measures at scale to existing facilities.

- Votorantim Cimentos plans to reactivate a 0.32 Mtpa calcined clay line at its cement facility in Nobres, located in the State of Mato Grosso, which would allow the site to increase its use of calcined clay as a substitute for emissions-intensive clinker and reduce the emissions of the final cement produced by up to 16%.

- Mizu Cimentos seeks to install pyrolysis units at their 1 Mtpa facility in Aracaju to produce energy from waste biomass to substitute fossil fuel use at the site. When fully implemented, the project could reduce emissions from cement production by up to 32%.

- The Eco Fusion consortium brings together the companies Argo Tech, Apodi Cimentos, CTEC, and Self Energy to install gasifiers at Apodi’s cement factory in Quixeré, producing energy from waste as a substitute for fossil fuel use. The first phase of the project aims to install an initial gasifier; subsequent phases will involve installing additional units, allowing an emissions reduction of up to 10% per tonne of cement.

From the aluminium sector, selected projects represent bold efforts to reach near-zero emissions production. While average emissions intensity of Brazilian aluminium stands at 4.2 tonnes of CO2 per tonne, far lower than the global average of 14.8 tonnes of CO2 per tonne, due to the widespread use of renewable hydroelectricity for aluminium smelting, the selected projects are going the extra mile to further reduce emissions.

- Alcoa aims to tackle one of the key remaining sources of emissions in the Brazilian aluminium value chain today – heat generation for alumina refining. Their project aims to electrify the boilers at their Alumar refinery in São Luis, which could reduce the emissions of the final aluminium they produce to as little as 0.6 tonnes of CO2 per tonne of aluminium.

- CBA is working to tackle the other key remaining source of emissions in the Brazilian aluminium value chain – process emissions from aluminium smelting – through a pioneering CCUS technology. Their technology is in the research and development stage and CBA ultimately aims to apply it at scale to their 0.43 mtpa smelter in Alumínio to bring the emissions of their aluminium below 2 tonnes of CO2 per tonne.

These projects will benefit from the ITA programme in Brazil, following a partnership agreement announced in July 2024 between ITA and MDIC, which positioned Brazil as the first country partner of the ITA. The ITA’s second partnership, for the Middle East and North Africa (MENA) region, was announced in November 2024 and is currently working within the United Arab Emirates, Bahrain and Egypt.